Inventions

with revolutionary engineering design

Inventions

with revolutionary engineering design

Multi-Functional Pile-Breaker

Please

refer to the patent office for all diagrams mentioned in

these descriptive texts

www.patent.gov.uk

A pile

breaker that can be driven by hydraulic fluid or air

pressure to break down concrete, and reinforced concrete,

piles of any shape, size or proximity to each other, without

damaging the integrity of the remaining structure. It is

designed to work under a system of extremely rapid,

short-shock pressure and release sequences resulting in

resonance shock waves transmitted within the designated

section of the pile. This, combined with the action of the

specially designed elliptical teeth, increases the

destructive effect on the concrete while protecting the

internal reinforcing structure of the piles.

Maximum

effect is gained when the chassis-main cylinders are paired.

This allows each tooth’s action to be combined with that

exerted by the directly opposing tooth.

The pile

breaker is operated remotely, from the source, thereby

ensuring that the operators do not suffer from vibrations,

noise, or dust inhalation. This also reduces the risk from

flying debris.

Technical field:

This

invention relates to a pile breaking machine that may be

driven by either hydraulics or pressurised air that allows

the top of reinforced concrete piles, (used in the

construction industry), to be removed without giving rise to

the handlers suffering any effects from vibration and other

related problems.

Background:

Since the

health and safety ruling on the effects of using vibratory

tools (known as white finger) it has been difficult for

construction companies to easily remove the tops from all

types of reinforced concrete piling. There are some machines

and methods that can remove the tops from specific piles

that are individually set at some distance from each other.

Nevertheless, many companies are still forced to return to

hand held vibratory machinery such as heavy breakers when

dealing with secant walling and other similar types. The

health restrictions on hours of use are both costly and time

consuming while remaining necessary.

This

invention is designed to operate best in matched pairs

joined together by high strength interwoven straps that are

themselves hydraulically adjustable and undergo constant

resetting with the pressure changes as the machine is

operated. The pile breaker is designed to work under a

system of extremely rapid, short shock pressure and release

sequences that result in resonance shock waves transmitted

within the designated section of the pile. This, combined

with the actual action of the specially designed elliptical

teeth, increases the destructive effect on the concrete

without causing damage to the internal metal reinforcement

structure of the piles.

This

invention provides the solution to all types of piling as it

can be manufactured in various shapes and sizes. An added

advantage is its remote operation, which ensures that no

personnel on site suffer any harmful effects from vibration

or other related problems such as noise, dust inhalation and

flying debris. As it is hydraulically driven, it also

incorporates a safety strap that will be the subject of

another patent application.

Essential technical figures:

This

invention (pile breaker) comprises of two aluminium

chassis-main cylinders (shown as no. 1 in the figures 1-10)

that incorporate six wet chambers (shown as no. 2 in figures

1-10) mounted with six smaller elliptical cylinders (shown

as no. 5 in the figures 1-10). These contain elliptical

pistons (shown as no. 8 in the figures 1-10) driven by a

hydraulic system. Each chassis-main cylinder (shown as no. 1

in the figures 1-10) also contains two dry chambers at its

far ends. Within each of these sections are located the

smaller round cylinders operating two high density straps

(shown as no. 10 in the figures 1-10). The high density

interwoven straps (shown as no. 10 in the figures 1-10) exit

the body of the main cylinders (shown as no. 1 in the

figures 1-10) through size matched holes (shown as no. 11 in

the figures 1-10) on both sides from the side facia of the

dry sections. The high density interwoven straps (shown as

no. 10 in the figures 1-10) are guided by and forced to roll

over a set of pulleys (shown as no. 7 in the figures 1-10).

Each main cylinder (shown as no. 1 in the figures 1-10) is

fitted with an air release valve (shown as no. 14 in the

figures 1-10) on its top, centre far end. The main cylinders

(shown as no. 1 in the figures 1-10) can be used

individually or as multiples of two and the number of

elliptical teeth (shown as no. 9 in the figures 1-10) can

vary to suit requirements. Each piston in turn, drives

elliptical teeth (shown as no. 9 in the figures 1-10), which

are manufactured of hardened steel, capped with an alloy,

such as (ra 3-10 or incoloy ds), that are both hard and heat

resistant. The chassis-main cylinder (shown as no. 1 in the

figures 1-10) is sealed and provides a reservoir for the

hydraulic fluid acting at the same time as a main cylinder

operating all elliptical pistons (shown as no. 8 in the

figures 1-10) at equal pressure. The chassis-main cylinder

(shown as no. 1 in the figures 1-10) has sides, which are

covered with shock absorbent latex that can be replaced when

worn. This feature provides a damping effect when working in

contact with adjacent piles, as is the case with secant

walling.

The

structure of the chassis-main cylinder (shown as no. 1 in

the figures 1-10) is constructed with inner reinforcing

walls (shown as no. 3 in the figures 1-10). These are

perforated to allow the flow of hydraulic fluid between the

inner sections. The inner reinforcing walls (shown as no. 3

in the figures 1-10) provide a dual function of moving the

centre of maximum pressure away from any walling. This

limits (almost entirely) the risk of deformation of the

outer walling and thus prolongs the lifespan of the pile

breaker.

All the

components of the chassis-main cylinder (shown as no. 1 in

the figures 1-10) are manufactured from a special type of

aluminium alloy, which has been formed, into plates under

High

pressure to provide maximum density and strength. The

manufactured components are then joined together by welding

(using the same material as welding rod). Corner joints

between these components are further reinforced by a joint

lining with the profile of a right angled triangle where the

hypotenuse is replaced by an arc. The additional arc

profiles have a solid formation. They are welded into place

in the process of manufacture. This additional rounding

feature of the interior corners vastly improves the

equalisation of pressure flow within the chassis-main

cylinder (shown as no. 1 in the figures 1-10) as well as its

rigidity.

Each paired

section is joined to the other by a wide, high density strap

(shown as no. 10 in the figures 1-10) made of interwoven

textile fibres. The strap (shown as no. 10 in the figures

1-10) is approximately 5mm thick and 150 mm wide. The straps

(shown as no. 10 in the figures 1-10) are able to withstand

& absorb approximately 3 times the maximum total level of

resulting forces. The strap's (shown as no. 10 in the

figures 1-10) also enable use of this invention on secant

walling where the distances between the piles are minimal.

Each strap (shown as no. 10 in the figures 1-10) is

connected to its chassis-main cylinder (shown as no. 1 in

the figures 1-10) by a fixed pin (shown as no. 15 in the

figures 1-10) joint on both opposite sides of one

chassis-main cylinder (shown as no. 1 in the figures 1-10).

Each pin is fitted with a drilled horizontal hole (shown as

no. 16 in the figures 1-10) in its bottom section into which

a retention device is to be inserted to hold it in its

preset position. On each opposite side is a constantly

adjusted hydraulically operated, round cylinder (shown as

no. 6 in the figures 1-10). Both of these round cylinders

(shown as no. 6 in the figures 1-10) receive the same amount

of pressure as the chassis, main cylinder (shown as no. 1 in

the figures 1-10). The free end of the strap (shown as no.

10 in the figures 1-10) is inserted into this receptor link.

This mechanism allows an optional design where one main

cylinder (shown as no. 1 in the figures 1-10) holds within

one of its side dry sections the round cylinder (shown as

no. 6 in the figures 1-10) and within its other dry section

a pin joint (shown as no. 15 in the figures 1-10). This

design is to be used as a single unit, which can be operated

independently where access to the pile(s) is restricted to

one face. Such cases would prevent mounting of the second

unit on the opposite side. This is done in such a way that

the short strap (shown as no. 10 in the figures 1-10) is

exchanged for a longer strap (shown as no. 10 in the figures

1-10) that goes round the pile and is joined back to the

same unit.

Each single

unit has four lifting eyes (shown as no. 13 in the figures

1-10) mounted on its upper surface, two just behind and two

in front of the imaginary line, which both bisects the

centre of gravity and is parallel to the foremost points of

the unit.

The

pressure hose linkage (shown as no. 12 in the figures 1-10)

is on the upper face, centrally placed at the rear of each

unit. When the units are used normally, (i.e. Paired), then

the hydraulic hoses are fed through a (t) or a (y) joint to

allow even distribution of pressure between both

chassis-main cylinders (shown as no. 1 in the figures 1-10)

and all twelve secondary (guiding) ones.

Although

the system described within this application uses as an

illustration, hydraulic fluid to provide the pressure

required for breaking the pile, exactly the same effect can

be achieved with compressed air. This alternate means of

providing pressure can be used with this exact structure as

the units are sealed against leakage.

Inside each

main cylinder (shown as no. 1 in the figures 1-10) there are

six smaller elliptical cylinders (shown as no. 5 in the

figures 1-10) welded into the front facia (shown as no. 4 in

the figures 1-10). Each one then provides the setting for an

elliptical piston (shown as no. 8 in the figures 1-10). Each

piston (shown as no. 8 in the figures 1-10) comprises of an

elliptical shape which is 75% hollow. The solid front of the

piston (shown as no. 8 in the figures 1-10) provides a

mounting for the breaking tooth (shown as no. 9 in the

figures 1-10). The piston (shown as no. 8 in the figures

1-10) is constructed of high density, pressed aluminium

alloy of the same kind. The solid front portion of the

piston (shown as no. 8 in the figures 1-10) contains an

elliptical hole of identical proportions to the tooth (shown

as no. 9 in the figures 1-10) mounting to allow for

attachment. The insides of the elliptical pistons (shown as

no. 8 in the figures 1-10) and elliptical cylinders (shown

as no. 5 in the figures 1-10) are treated with a hardener to

ensure a long life span. Elliptical shape design of the

teeth, cylinders, & pistons ensures that the elliptical

teeth (shown as no. 9 in the figures 1-10) remain in a

preset horizontal cutting position as rotation is

eliminated.

Each tooth

(shown as no. 9 in the figures 1-10) comprises of an

elliptical solid shape tapered towards the front. The

breaking surface is formed by two concave indentations at

top of the tooth (shown as no. 9 in the figures 1-10) and a

highly sharpened triangular front edge and a flat horizontal

underside. This construction of the tooth (shown as no. 9 in

the figures 1-10) allows it to break the concrete structure

while avoiding causing damage to any part of the internal

metal reinforcements. The elliptical teeth (shown as no. 9

in the figures 1-10) are designed as exchangeable to achieve

lower cost of maintenance.

The pile

breaker construction design can also be made of smaller

singular sections connected to each other by means of

classical pin-hole joints or by any other suitable means.

The

elliptical design of the cylinders used can also be replaced

with classical round shaped ones while the avoidance of

teeth turning can be achieved by other means than mentioned

within this description.

Each

chassis-main cylinder (shown as no. 1 in the figures 1-10)

is fitted with six elliptical teeth (shown as no. 9 in the

figures 1-10); each mounted on it is own piston/cylinder

structure, and protruding from the front face part between

the two reinforced facia (shown as no. 4 in the figures

1-10) in a curve.

The pile

breaking action is executed by pairs of elliptical teeth

(shown as no. 9 in the figures 1-10) acting against each

other on opposite sides of the concrete pile. This occurs

when two units are used together. It is this formation which

results in maximum horizontal interior structural damage,

that is solely limited to the concrete part of the pile

between the elliptical teeth (shown as no. 9 in the figures

1-10) and its adjacent structural surroundings. This means

providing that the pile breaker is set at a small distance

from where the pile is required to be effective then no

damage occurs to the integrity of the remaining pile.

Accompanying figures:

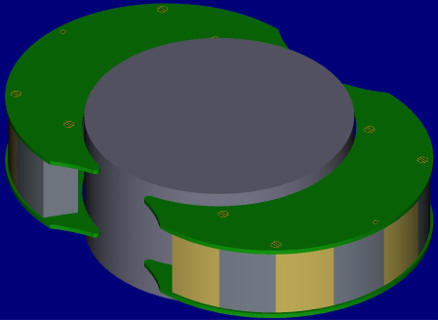

Fig (1/10)

shows the full top view of paired pile breaker version, in

operation on 3 piles of secant concrete walling.

Fig (2/10)

shows the top detail view of a single pile breaker main

cylinder.

Fig (3/10)

shows the front view of the first main cylinder section

incorporating smaller round cylinders and four guiding strap

pulleys.

Fig (4/10)

shows the front view of the second main cylinder section

incorporating retention pins and two guiding strap pulleys.

Fig (5/10)

shows the main cylinder dry section top detail view

incorporating strap join mechanism created by pin and

pulley.

Fig (6/10)

shows the main cylinder dry section top detail view

incorporating strap guiding and extension mechanism created

by the use of round hydraulic cylinders and a set of guiding

pulleys.

Fig (7/10)

shows the top cut detail position view of elliptical

cylinders and pistons.

Fig (8/10)

shows the front view of elliptical cylinder/pulley position

in detail.

Fig (9/10)

shows the elliptical cylinder and tooth front view in

detail.

Fig (10/10)

shows the main cylinder dry section detail incorporating

pulley and pin it their positions.

Claims:

1- A

hydraulic pile breaker that is adjustable and can be

manufactured to cope with any size or shape of concrete pile

and its reinforcing bars.

2- A

pile breaker as claimed in claim 1, but driven by compressed

air.

3- A

hardened triangular breaker tooth (shown as no. 9 in the

figures 1-10) with two concaved top sides.

4- An

adjustable high density interwoven linking strap (shown as

no. 10 in the figures 1-10) controlled by hydraulics.

5- An

adjustable high density interwoven linking strap (shown as

no. 10 in the figures 1-10) as claimed in claim 4, but

controlled by compressed air.

6- A

pile breaker as claimed in claim 1 & 2 that can operate as a

single unit.

7- A

pile breaker as claimed in claim 1 & 2, that can operate

under fresh or salt water.

8- A

pile breaker as described in claims 1 & 2 which is

constructed of dense aluminium alloy or any other metallic

or metallic alloy material.

9- A

pile breaker as described in claims 1 & 2 that is

constructed of any suitable dense polymer.

10- A pile

breaker as claimed in claim 1 that is driven by hydraulic

fluid pressurised from a direct pump or other suitable

source such as a tele handler or an excavator.

11- A pile

breaker as claimed in claim 2 that is driven by pressurised

air from a stand alone compressor or other suitable source.

12- A main

cylinder (shown as no. 1 in figures 1-10) is claimed where

the body acts as a fluid/air reservoir and smaller

elliptical cylinders (shown as no. 5 in the figures 1-10)

are contained therein.

13- A pile

breaker as claimed in claim 12 where the main chassis (shown

as no. 1 in the figures 1-10) is full of air (not

pressurised) and small hydraulic hoses feed each elliptical

cylinder (shown as no. 5 in the figures 1-10) or round

cylinder (shown as no. 6 in the figures 1-10) individually

as in a standard cylinder operation.

14- A pile

breaker as claimed in claim 13 where the standard cylinders

are operated by compressed air fed individually.

15- An

exchangeable latex side padding functioning as a vibration

damper between and adjacent concrete piles is claimed.

16- A pile

breaker substantially as describer herein with reference to

figures 1 to 10 of the accompanying drawings.

Please

refer to the patent office for all diagrams mentioned in

these descriptive texts

www.patent.gov.uk

TOP